Metal Flashing System

Flashing roofs create intersections and terminations of systems and surfaces. As previously mentioned, it is designed to keep water from entering areas where there is a roof malfunction.

It usually comes in the form of an impermeable material, a thin piece of metal, in this case, installed at strategic junctions of a roof system to create a more weather-resistant envelope.

Metal Flashing is usually found around the base of the chimney and skylight, a place where you insert a hole in the roof for the purpose of setting up a facility. Entire holes can be difficult to seal, and intersections expand and contract when temperature and humidity change. The flashing items remain sealed while allowing for this movement.

The flashing can be set up like shingles, in which one piece laps the other or it can be sealed to act as a continuous surface. Either way, flashing can also be reconfigured with a non-continuous profile to prevent water from entering through surface tension.

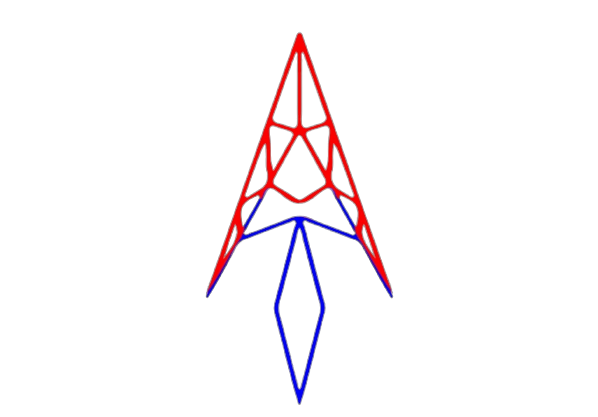

Types of Flashing

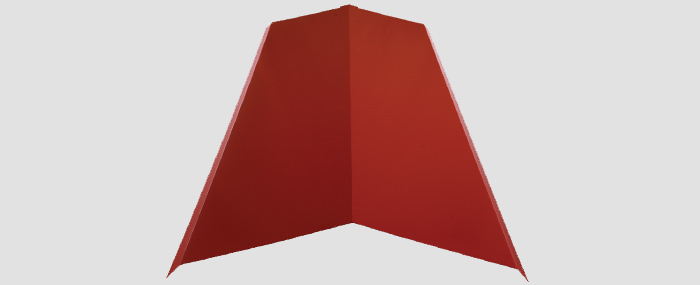

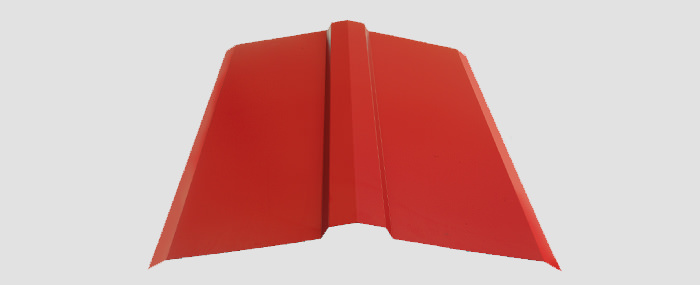

Ridges flashing

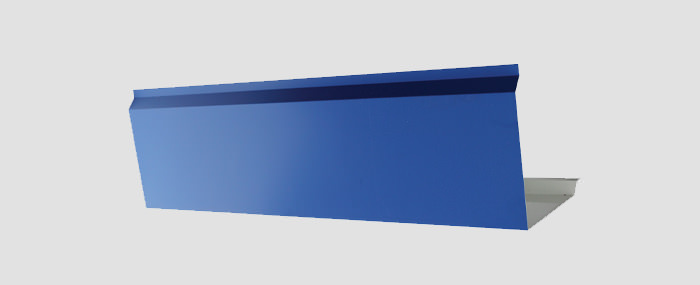

Fascia

Aprons

Barge Capping

Eave Gutters

Valley Gutters

Eaves & Drip Edge Flashing

Window Flashing

Corner Flashing

There can be a variety of materials, ranging from flashing plastic and rubberized asphalt. It can be exposed or hidden. Metal flashing is usually exposed, but can be installed under shingles or outer coverings.

Flashing ceilings can come in the form of roofs or membranes; each has its best use. The membrane is one piece and can simplify the installation around the projections of the roof.

Commonly used metals for flashing:

Copper

Lead

Lead-coated copper

Galvalume

Malleable metals such as aluminum, zinc and stainless steel

Plastic and other soft materials may be used, but must be able to withstand direct sunlight and weathering.

Flashing for Pre engineered buildings

Roof flashing is used around projections or disconnects what else? Its main function is to divert water away from seams or joints and into roof basins where water runoff is concentrated. The glare of roof penetration is for water-proofing locations where pipes, supports, cables, and other roof protrusions are made.

Channel flashing the roof is specially glazed which is shaped like a “U” or a channel, where it joins the wall. The drip edge serves a similar purpose. Another design for the roof edges is called kick-out flashing. It is installed under a roof and wall intersection, with the lowest part formed to deflect water away from the wall.

Valley flashing is for the protection of the valley where two roof planes intersect, instead of channel flashing.

It is used on windows, areas of structural support, and other blockages in the wall. It operates by directing water towards the pores of the fur.

Thickness of the wall through the flashing wall. A special type of wall flashing, flashing glitter or a pan pan; It is hidden under the frame of windows or doors to prevent leakage of moisture. Cap flashing, also known as drip cap, is installed above windows and doors.

It is very self-explanatory where it is used. Chimney flashing is another special flashing material.Step flashing is also known as soccer or base flashing. This is a method of installation where the flashing pieces overlap each other in “steps”. Kick-out flashing uses this technique.